BRT Hartner’s Feed & Metering Hopper has for many years been available in a wide range of both standard designs and bespoke tailor-made solutions. Since the beginning of the year BRT Hartner GmbH have relaunched this range of feed, metering and dosing hopper to include a new design concept, now featuring a common segmented modular bunker structure which is utilised on both the D-Series Feed & Metering Hopper and the BO-Series Bag Opener range.

When combined with the BO-Series Bag Opener, BRT Hartner GmbH can provide two distinctive designs to accommodate the processed material. The LWP-Range (light-weight packaging) offers a lighter construction and is suitable for applications involving the processing of dry mixed recyclables (DMR). The MSW-Range (municipal solid waste) provides a heavier robust construction inclusive of increased moving floor and side wall material thicknesses. This range of BO-Series bag openers is better suited to applications concerning materials with high glass content, typical UK “black-bag” waste and other heavier materials.

As with the previous hopper design BRT Hartner GmbH offer three working widths of BO-Series Bag Opener however the previous largest model has now increased in width from 2.100m to 2.300m. This increase in working width, combined with a revised range of ripping drum cycles/rotating speeds of 18, 22 or 26 cycles, now provides an increase in throughput volume for BRT Hartner’s largest model, thus ensuring the range can accommodate the higher throughputs associated with the larger material recycling facilities (MRF’s).

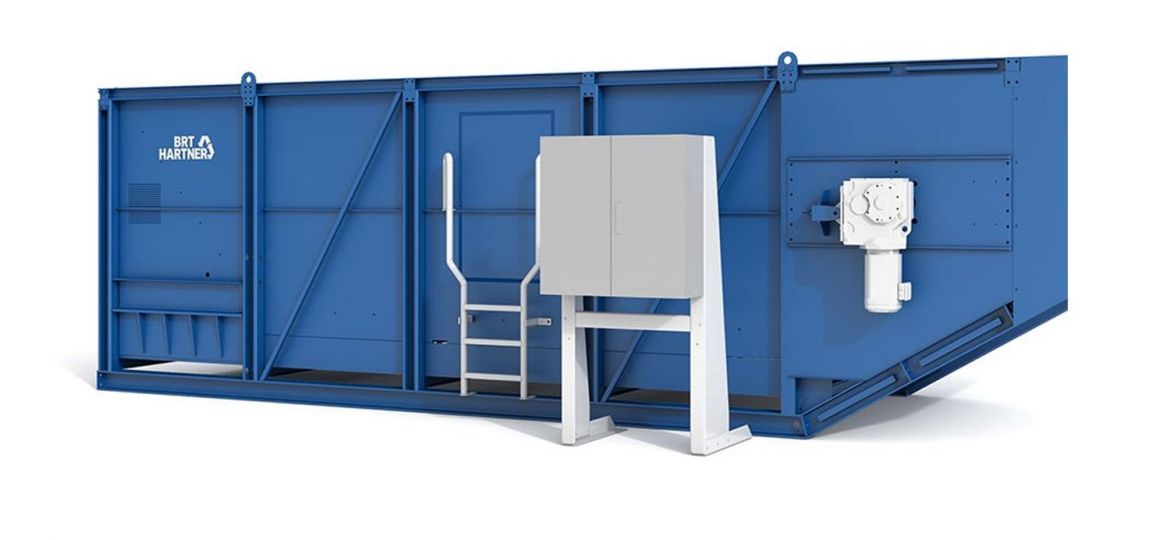

The new segmented modular bunker design also provides a new range of usable hopper lengths, now starting at 4.000m. Standard bunker lengths are available in 2.000m increments up to 14.000m, however BRT Hartner can still offer bespoke solutions to meet your exact requirements if required. To improve operator access for maintenance purposes, the moving floor drive arrangement has been relocated to the rear of the machine. Whilst this increases the overall length of the machine by approx. 1.500m, relocating the drive assembly from beneath the moving floor to the rear of machine greatly improves maintenance access. BRT Hartner GmbH have also redeveloped their moving floor design to now incorporate the DYNAM-Floor. This dynamic system encompasses overlapping, frequency-controlled movements to improve operation, efficiency and longevity thus providing a faster conveying action of the stored/processed material equating to an increase in capacity and processing rates.

The BRT Hartner D-Series Feed & Metering Hopper and BO-Series Bag Opener are now fully equipped to handle your material and processing needs. For more information please don’t hesitate to contact us…